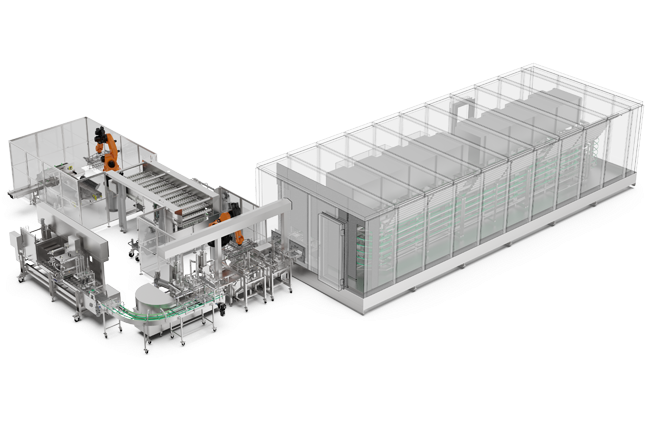

The complete extrusion and filling lines of Flexiline represent a highly advanced solution for ice cream production in various shapes and packaging. This modular system offers a range of key features for efficient and flexible production:

Modularity

The Flexiline system is modular and includes various workstations for the production of extruded, cut, wrapped, or container-filled ice cream, such as cones or wafer cups. This flexibility allows for the production of a wide range of frozen products.

Cooling

The cooling system consists of aluminium fin evaporators with variable pitch and refrigeration units. Different refrigerant options, including freon, ammonia, or CO2, can be chosen based on specific needs.

Moreover, the Flexiline tunnel offers the option of on-demand sequential defrosting, ensuring effective maintenance and cleaning of the system. This helps maintain tunnel performance over time and ensures the quality of the frozen product.

Automation and robotics

The pick-up group from the workstation can be managed by a plate system with air-driven clamps, operated by a Kuka-type robot. This simplifies management and maintenance operations, reduces the time required for product format changes, and optimizes space.

Advanced control:

The control panel of the production line is equipped with a Touch Screen Operator Panel, PLC, action switches, and emergency buttons. It is possible to integrate an industrial PC for data exchange with factory ERPs, ensuring compliance with Industry 4.0 regulations. The choice of control hardware can be customized, such as with SIEMENS, ROCKWELL/ALLEN-BRADLEY, or other comparable options.

Product variety

This line allows for the production of a wide range of frozen products, including popsicles, cones, cups, sandwiches, bars, cakes, bonbons, and other market innovations. Dedicated equipment for specific dosages can be added to expand the product range. The Flexiline line is delivered turnkey, complete with all necessary accessories and connections.