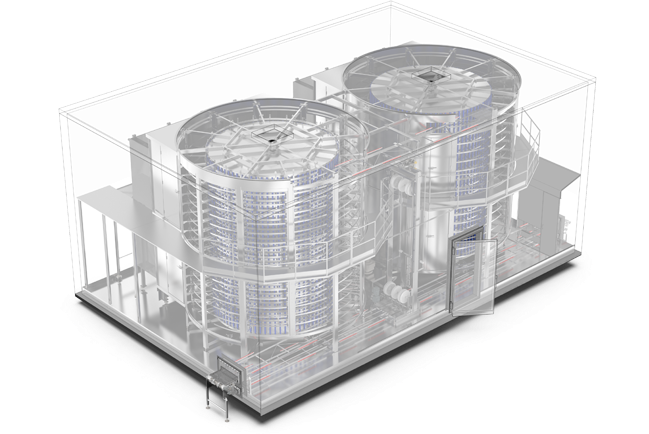

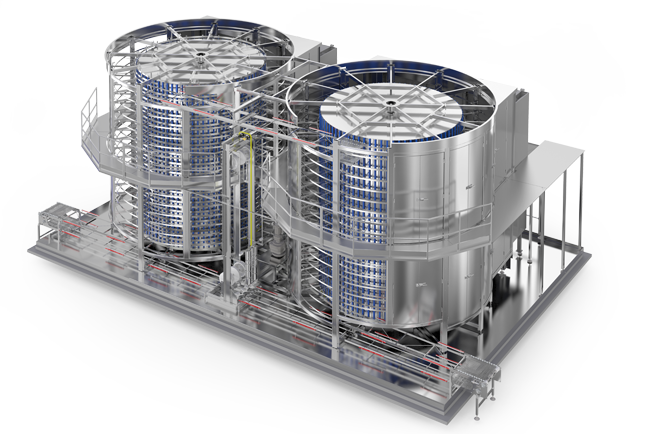

Our hardening tunnel is designed for both packaged and unpackaged products with a robust, fully stainless steel structure. This tunnel consists of an isothermal chamber inside which a spiral conveyor belt runs wrapped around a single or double drum, depending on specific requirements. The number of turns per drum and the conveyor width vary based on the required hardening time and container sizes.

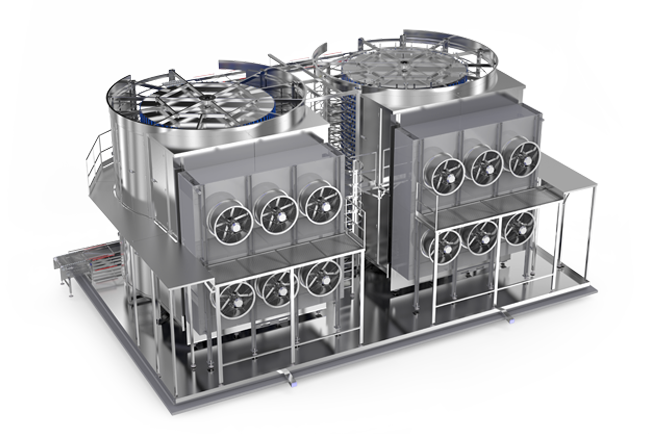

The system is designed with a horizontal airflow parallel to the surface of the spirals, ensuring a high heat exchange coefficient regardless of the quantity of product on the conveyor. The tunnel floor is made of a welded stainless steel sheet tank installed on a solid reinforced concrete base, with adequate insulation to prevent water stagnation and ice formation on the floor. Additionally, the tank is equipped with drainage channels for washing and defrosting water, with the right slope for safe water management.

The cooling system, essential for the hardening process, is sized according to production needs and can use refrigerants such as freon, ammonia, or CO2, based on specific requirements. Evaporators, complete with axial fans, extend across the entire height and width of the spirals, ensuring even air blowing over all spirals.

The line's control panel is equipped with a Touch Screen Operator Panel, PLC, operation switches, and emergency buttons. The control hardware can be of high quality, such as SIEMENS, ROCKWELL/ALLEN-BRADLEY, or equivalent. We provide the turnkey line, complete with all the necessary accessories and connections to ensure robust operation.

Furthermore, the spiral hardening tunnel offers the option of sequential defrosting upon request, ensuring effective maintenance and cleaning of the system. This contributes to maintaining tunnel performance over time and ensuring the quality of the frozen product.