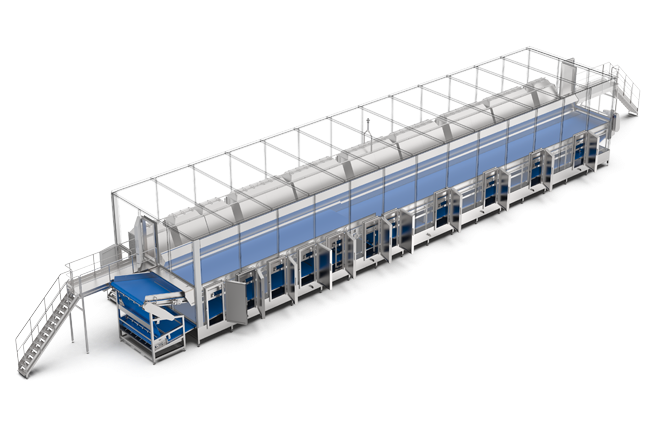

The fluidized bed tunnel is an advanced solution for freezing cubed or granulated products with a high water content, such as cooked cereals, cooked rice, and especially blanched peas. This system provides an effective and fast freezing procedure to maintain the quality and consistency of the products.

The tunnel structure consists of two perforated horizontal conveyor belts and a high-capacity ventilation system, which allows propelling the granules into a bed of air traveling vertically. The air temperature used for this process is extremely low, reaching -40 °C, ensuring immediate freezing of the small granules. This rapid temperature drop ensures that the product does not clump together once frozen, ensuring a 'free-flowing' consistency ideal for all subsequent processing stages.

Additionally, the fluidized bed tunnel offers the option of sequential defrosting upon request, ensuring effective maintenance and cleaning of the system. This contributes to maintaining tunnel performance over time and ensuring the quality of the frozen product.