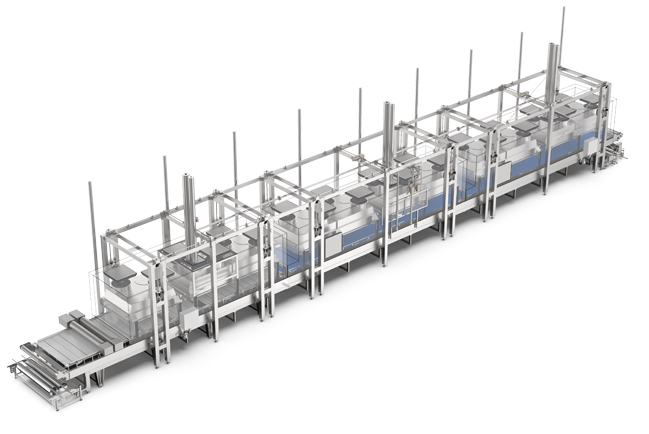

The 'Super Contact' cooling tunnel is an advanced device used for the freezing process of liquid sauces and seafood. This tunnel is designed to ensure efficient and high-quality freezing, regardless of the consistency of the sauces, which can range from very fatty to almost entirely watery, such as broths.

The structure of the tunnel consists of a refrigerated plane with aluminum plates containing a refrigerant fluid. These plates are designed to ensure uniform and controlled cooling. A polyethylene (PE) film with a thickness between 40 and 70 microns flows over the plates, held in place by side edges that contain the liquid product. This PE film helps improve the contact between the product and the refrigerated plates, ensuring quick and effective freezing.

The tunnel is equipped with fiberglass hoods inside which ventilated cooling batteries are installed. These batteries cool the top of the sauces, contributing to creating an ice sheet at a temperature of -3/-4 °C. This ice sheet passes under a mechanical cutter that determines the final shape of the product, which can be cubes, prisms, or other desired shapes. After cutting, the product moves to a subsequent module for the final freezing phase.

Furthermore, the 'Super Contact' tunnel offers the option of sequential defrosting upon request, ensuring effective maintenance and cleaning of the system. This contributes to maintaining tunnel performance over time and ensuring the quality of the frozen product.