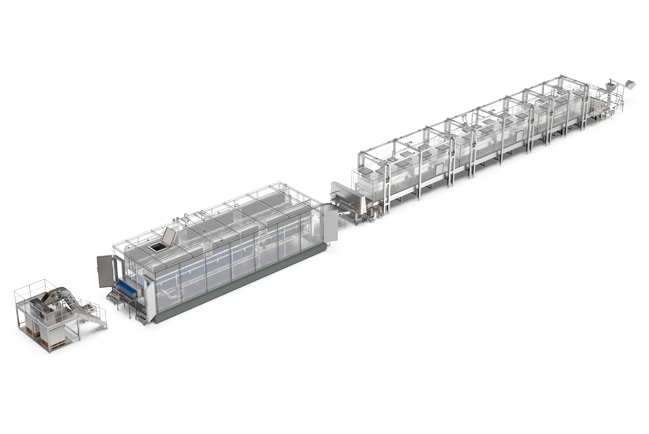

We provide automatic lines for the preparation of sauces that ensure an efficient and high-quality production process.

Our lines include:

- Liquid dosing systems equipped with flowmeters or load cells for accurate control of quantities.

- Solid dosing systems that ensure precision in measuring solid components.

- Jacketed cooking tanks with capacities ranging from 1,000 to 2,000 liters, with steam heating under pressure up to 5 bar for optimal cooking.

- Condensate recovery system from fumes to contribute to the energy efficiency of the process.

- Volumetric pumping systems to ensure the integrity of solid parts during transport.

- Optional homogenizers to ensure a consistent sauce texture.

- Scraped surface tube coolers that ensure a rapid cooling process while maintaining product quality.

- Jacketed storage tanks for the finished sauce with cooling systems using chilled water or glycol.