Our production lines for long dry pasta, particularly for frozen lasagna, are designed with precision and flexibility to adapt to the specific needs of each product. Each line is structured into clearly defined areas, custom-designed based on the characteristics of the product to be created. The components include:

Preparation area:

- Ingredient feeding and mixing group.

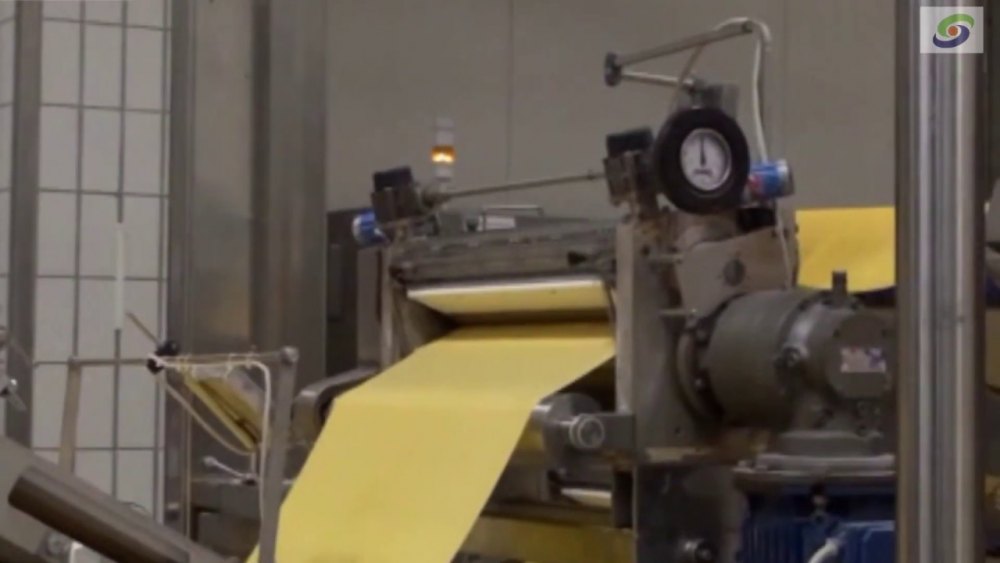

Shaping/extrusion/forming area:

- Continuous production machine for fresh pasta.

- Conveyor belts.

- Rolling mills.

- Puff pastry pasteurization group.

- Blancher cooking group.

- Cooling/drying group.

- Oiling group.

- Cutting system.

Freezing area:

- Single or double spiral tunnels.

Packaging and end-of-line area:

- Series of conveyor belts with grippers.

Our supply includes the integration of mechanical, electrical, and software aspects for all equipment installed on the production line. We provide advanced solutions, ensuring an efficient and reliable production process for long dry pasta, especially for frozen lasagna.