Our production lines are organized into clearly defined areas, custom-designed based on the product to be produced. Each area plays a crucial role in the production process, ensuring efficiency and quality. Here's an overview of the main areas:

Preparation area:

- Ingredient feeding and mixing group to create a high-quality base.

- Shaping/extrusion/forming area.

- Continuous production machine for fresh pasta.

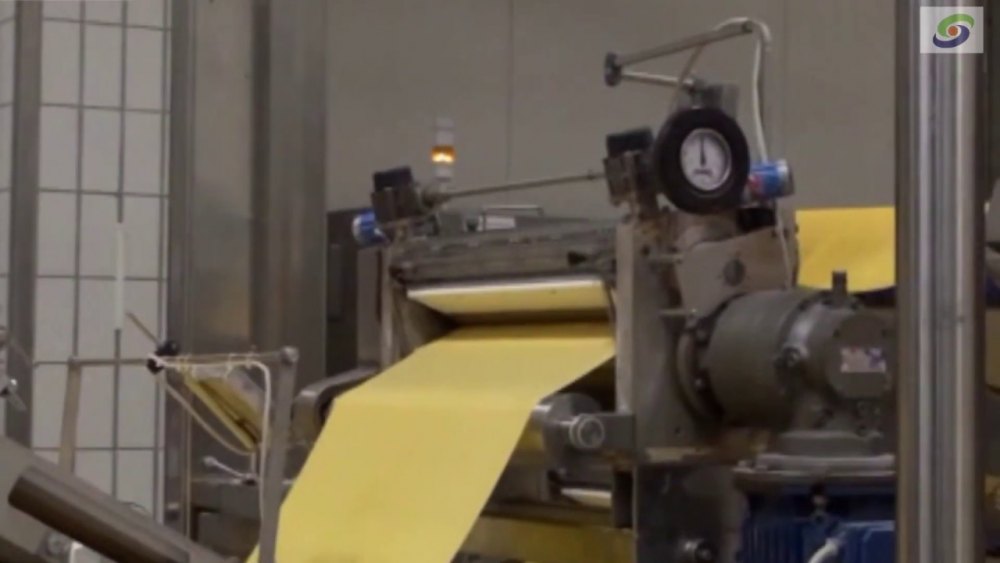

- Conveyor belts for the smooth movement of products. Rolling mills for sheet processing.

- Puff pastry pasteurization group.

- Blancher cooking group.

- Cooling/drying group.

- Oiling group.

- Cutting system for creating desired shapes.

Freezing area:

- Single or double spiral tunnels to ensure efficient freezing.

Packaging and end-of-line area:

- Automatic cage filling to organize and prepare the product for the next phase.

The supply includes careful integration of mechanical, electrical, and software aspects of all equipment mounted on the line. We are committed to providing precise, complete solutions to optimize production and ensure maximum customer satisfaction.