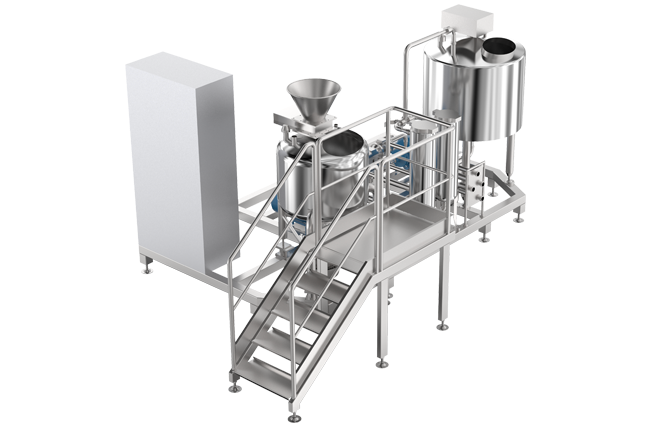

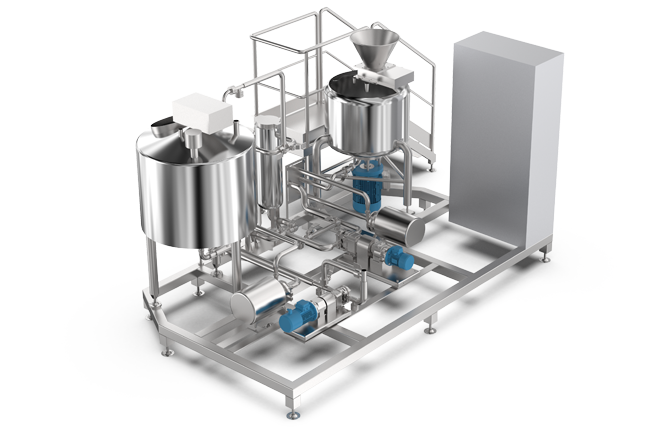

Batter preparation systems

We offer a complete line dedicated to batter preparation, designed to ensure an efficient and accurate process. Our offering includes:

Dosing and control systems:

- Liquid dosing systems with quantitative control through flowmeters or load cells.

- Volumetric pumping systems to preserve the integrity of the batter.

- Loading systems, manual or automatic, for ingredients and powders through hoppers sized according to the quantity of product to be loaded.

Hopper structure:

- Profiles in stainless steel AISI 304 with a chequered steel floor.

- Perimeter railing in stainless steel tube with a kick plate.

- Stainless steel AISI 304 step ladder for easy access.

- Hoppers connected to the beams via anti-vibration mounts to ensure weighing accuracy.

- Cylindrical stainless steel buffer hoppers with a protective grid and removable lid for manual loading.

Mixing Systems:

- Stainless steel AISI 316 mixers with motors mounted on load cells for the weight detection of powder ingredients and liquids.

- AISI 316 stainless steel storage tanks with a motorized agitator, jacketed and insulated, cooled with chilled water or glycol.

- Pipes, valves, pumps, thermometers, and probes sized and calculated according to the factory layout.

Electrical System:

- Complete power and signal electrical system with an electrical cabinet.

- Programmable control logic using Siemens S7-1500 PLC and a 7” Siemens touchscreen mounted on the cabinet door.

Our solution offers high reliability and control, ensuring precise and efficient batter preparation.