Sticks, nuggets, pizzas, crêpes, pastas, vegetables

Covering a wide range of products such as sticks, nuggets, pizzas, crêpes, pastas, and vegetables, our complete production lines are carefully designed to ensure efficiency and quality.

The structure of these lines is divided into key areas, each designed to play a specific role in the production process:

Preparation area:

- Mixers, blenders, and grinders for creating high-quality bases.

- Cooking tanks for sauces and batter preparation.

Shaping/extrusion/forming area:

- Cutting and cubing systems to shape the products.

- Pressing and folding stations for creating structured products.

- Coating with batter and breading.

- Cooking options, including steam, water, or infrared lamps, followed by the frying phase.

Dosing and filling area:

- Precise dosing and filling systems for cheese, chocolate, and creams.

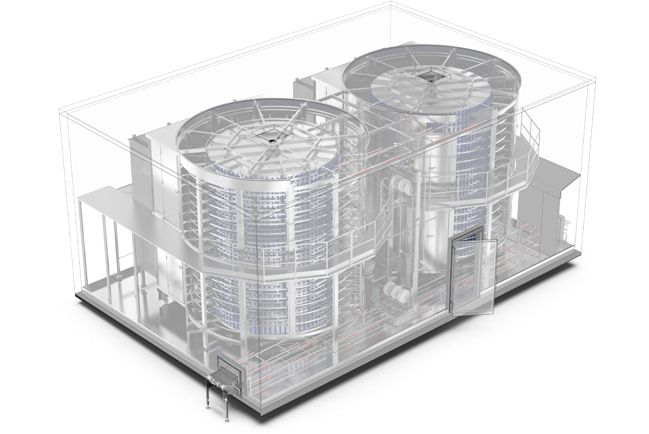

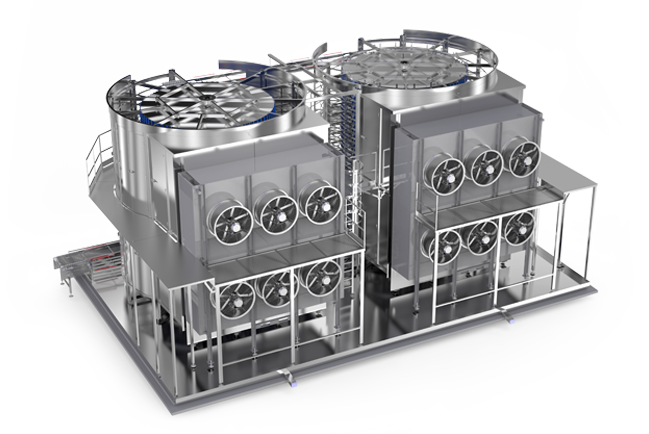

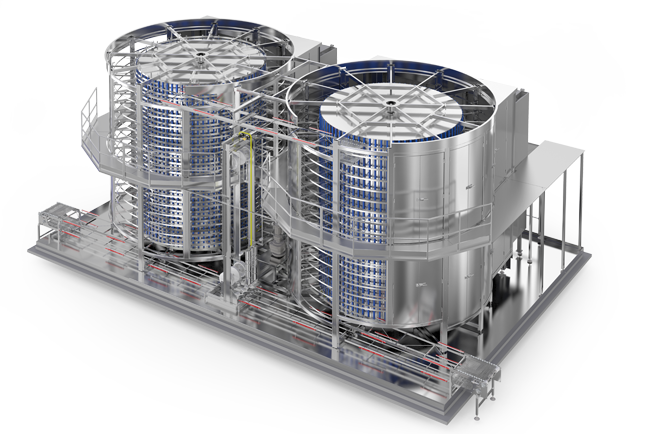

Freezing area:

- Single or double spiral tunnels to ensure an efficient freezing process.

- Linear tunnels with impingement technology (high-speed air) for optimal results.

Packaging and End-of-Line Area:

- Packaging machines.

- Cartoners.

- Use of Delta robots (ABB flexpicker) and anthropomorphic robots for secondary packaging.

- Wrapping machines.

- Palletizers to facilitate the management and storage of finished products.

The supply includes careful integration of mechanical, electrical, and software aspects of all equipment mounted on the line. Our commitment is to provide complete solutions that optimize production and ensure maximum customer satisfaction.