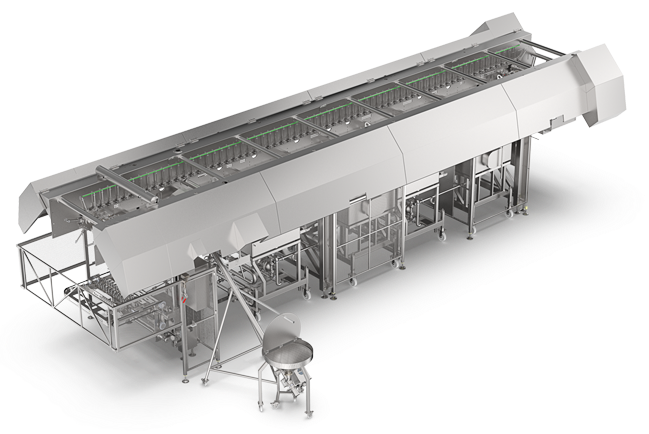

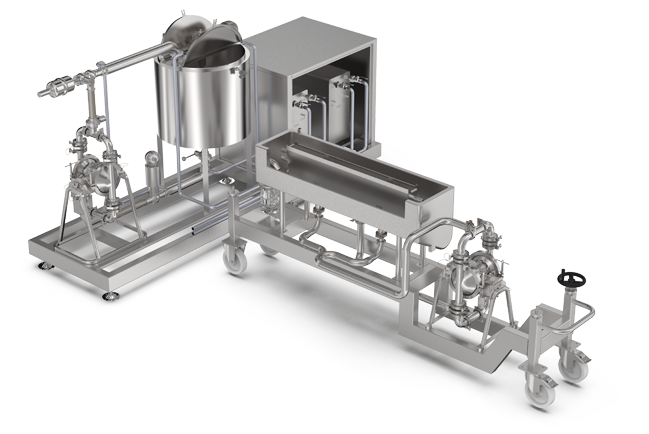

The Stino dipping and coating system is a versatile solution for glazing products with or without a stick, offering a range of advanced features for the food industry.

The glazing system is designed for the immersion of products in chocolate or other coating ingredients and consists of:

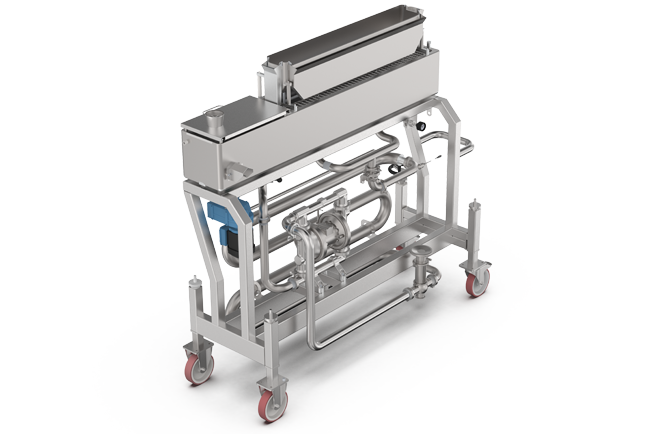

A robust stainless steel frame that ensures strength and durability.

A sliding guide with a double chain for transporting the blades, allowing smooth movement of the products through the glazing process.

A chocolate dipping tank with a double tank (upper and lower), designed to maintain the chocolate at the desired temperature and allow uniform immersion of the products.

The traction system is controlled by brushless motors, ensuring quiet and precise operation. Additionally, the dipping system is highly flexible, allowing adjustment of the immersion depth and time based on the specific product requirements.

Depending on the products to be glazed, the equipment can be equipped with multiple dipping tanks. For example, in the production of Magnum Double, two tanks are used for the two types of chocolate and one tank for caramel, with nitrogen tanks for the immediate hardening of the coating.

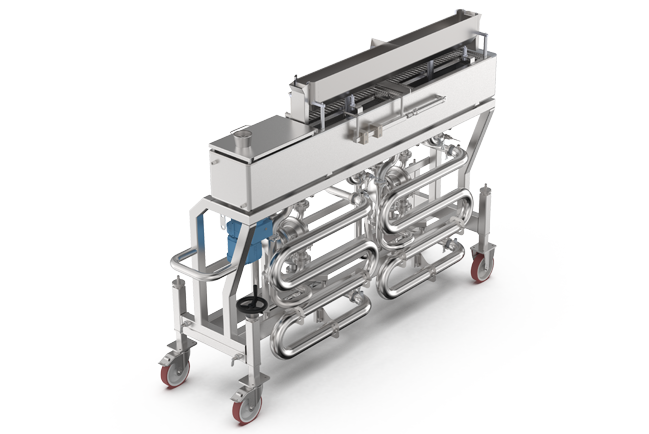

Furthermore, the system offers the possibility to use tanks with two or three chocolate colors and handle chocolate containing inclusions with a maximum size of 2 cm. It is highly adaptable to different product recipes and allows variation in immersion time and draining time without affecting the overall production capacity.

This glazing system can also be used with ingredients other than chocolate, such as fruit juices, as in the case of Solero production.

In the case of large-sized inclusions, the surface of the underlying tank is inclined and equipped with an auger that effectively manages the settling of inclusions, such as granules, and maintains a constant suspended concentration of the inclusion with the help of a volumetric recirculation pump.

The tank is completed by a 150 liter tank with double-wall heating to maintain the chocolate temperature constant. It is equipped with a transfer pump to feed the tank and a Tool Temp temperature control system to ensure the quality of the coating.

To complete the entire production line, STINO also provides jacketed connecting pipes for the transport of the chocolate flow and a granule dosing control system based on the amount of chocolate fed.

Stino is available in three models, each with different production capacities to meet the specific needs of the industry:

- STINO 12-330 (330 pieces per minute)

- STINO 16-440 (440 pieces per minute)

- STINO 20-550 (550 pieces per minute)