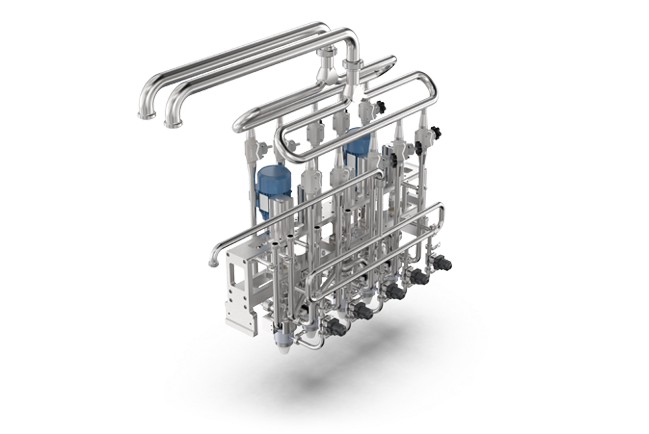

The equipment for ice cream production includes a wide range of highly versatile and configurable dosers to meet the specific needs of ice cream novelties. These dosers are designed to ensure precision in dosing and flexibility in use, regardless of the type of ice cream being produced. The main types of dosers available are described below:

Time elapse dosers or volumetric dosers:

Time elapse dosers allow the filling of specific quantities of ice cream based on the set time, making them ideal for continuous production. Volumetric dosers dose the ice cream based on volume, ensuring precise measurement of portions.

Rotary dosers:

Rotary dosers are designed for single and dual-flavour ice cream production lines, allowing the injection of syrup both internally and externally. These dispensers offer a high degree of automation, ensuring a uniform distribution of ice cream and syrup.

Windmill dispensers:

Windmill dispensers are designed to dispense ice cream evenly. This method ensures a uniform distribution of decorated ice cream in segmented sectors.

Dolloping and swirling dosers:

These dosers are ideal for producing ice creams with various decorations, such as dollops of cream or swirls. They enable the creation of aesthetically appealing products.

Additionally, STIM offers customized solutions upon request to meet specific customer needs. This means that the dosers can be adapted to production requirements.

It is important to emphasize that STIM provides assistance in installing the dosers on its own production lines or those of other manufacturers, ensuring easy installation and efficient operation.