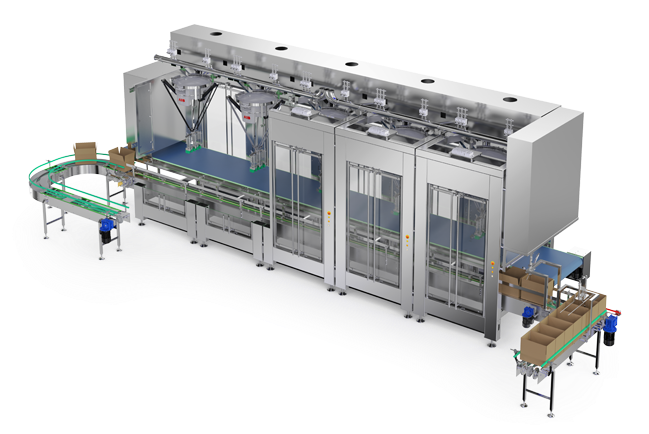

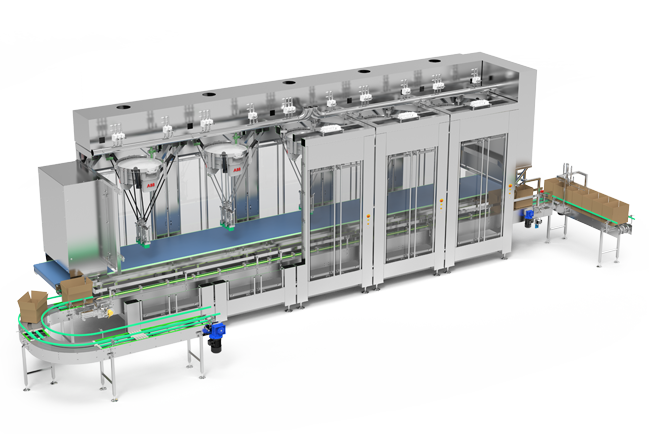

STIM introduces an advanced robotic pick&place system dedicated to the efficient boxing of products. Our company provides tailor-made solutions for the boxing and casing of products of various types and sizes, leveraging our extensive experience in the food processing industry. Our range of solutions includes the use of anthropomorphic robots, delta robots, and pick&place systems developed in-house by STIM.

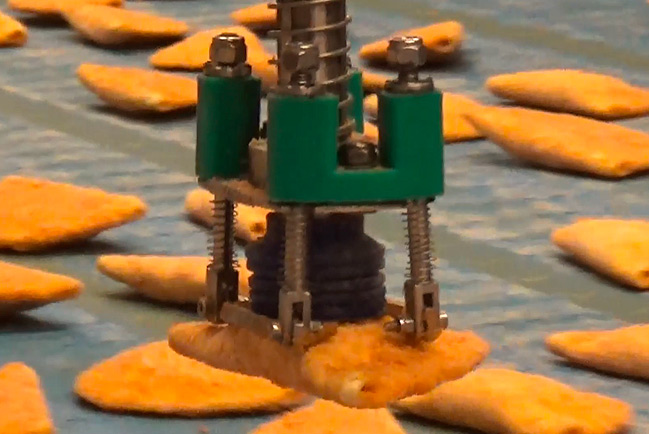

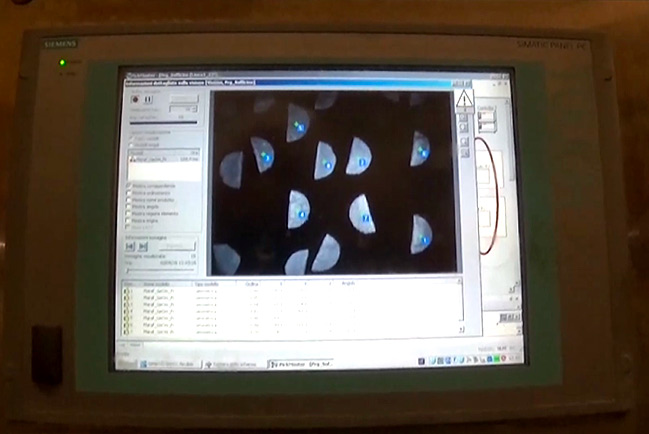

In the design process, STIM customizes gripping devices, using mechanical or pneumatic solutions with suction cups, based on the specifications of the products to be boxed. Our automatic product retrieval system, known as FLEXPICKER, can handle loose or pre-packaged products randomly arranged on a sliding conveyor belt. Using a camera, the system identifies the product's position and picks it up with a robotic arm equipped with suction cups, precisely placing it inside the packaging carton.

Each arm's maximum picking capacity is 100 pieces per minute, ensuring a fast and efficient process. Our systems are designed modularly, allowing adaptation to variable throughputs ranging from a few hundred to thousands of pieces per minute. This flexibility makes our systems suitable for a wide range of applications, ensuring maximum versatility and productivity for our customers.