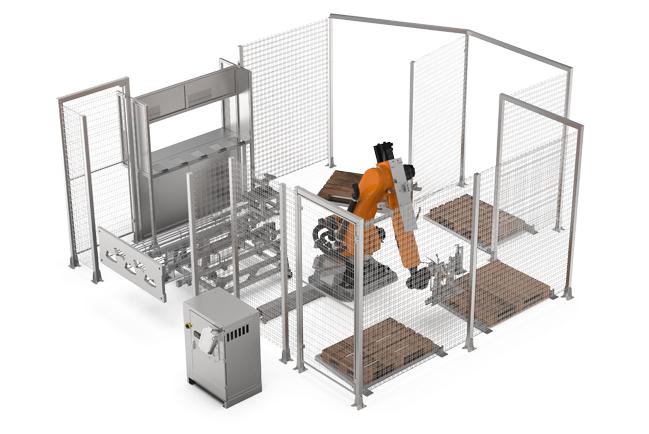

The concluding phase of the production process is entrusted to our advanced end-of-line and palletizing solutions. Our palletizing cells, custom-designed based on specific customer needs, represent an effective blend of advanced robotics and a programmable automatic palletizing system.

These cells are characterized by remarkable flexibility, allowing our palletizing system to simultaneously handle from one to five pallets, each with up to 5 distinct products. Versatility is further accentuated by the ability to manage pallets of different sizes and materials, even simultaneously, ensuring high adaptability to various production requirements.

In addition to efficient pallet management, we offer integrated options for labelling or marking that clearly and precisely identify each pallet. This additional feature not only contributes to product traceability but also enhances logistical management and production flow visibility.

STIM provides both conveyors for products destined for palletization and conveyors for the pallets themselves. We offer the option to integrate stretch film wrappers and provide software interfaces for integration with automatic shuttles, such as AGV or LGV, from any other supplier.

In summary, our end-of-line and palletizing solutions not only optimize production efficiency but are also designed to dynamically adapt to various working conditions, providing a high level of customization to meet the specific needs of each customer.