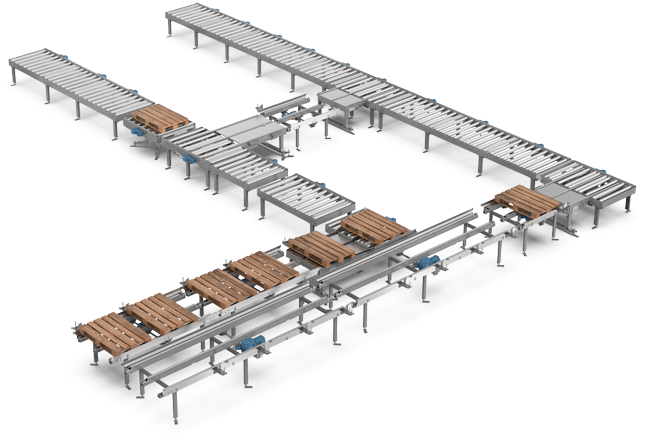

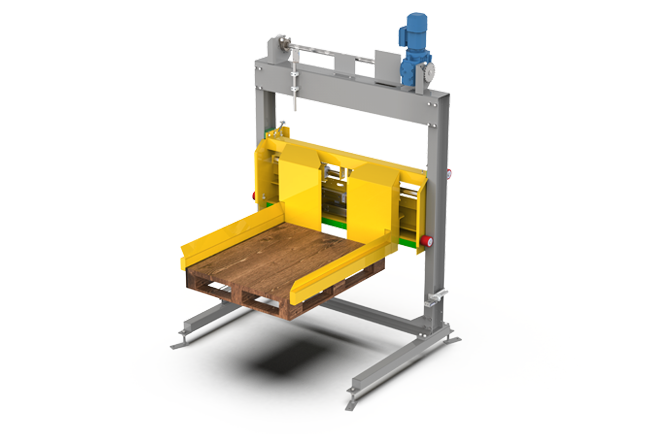

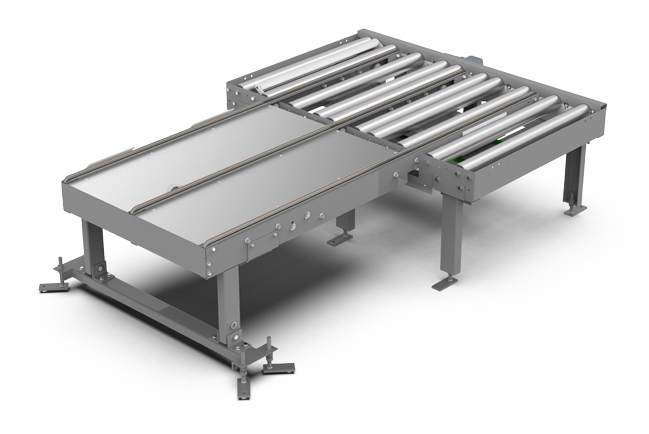

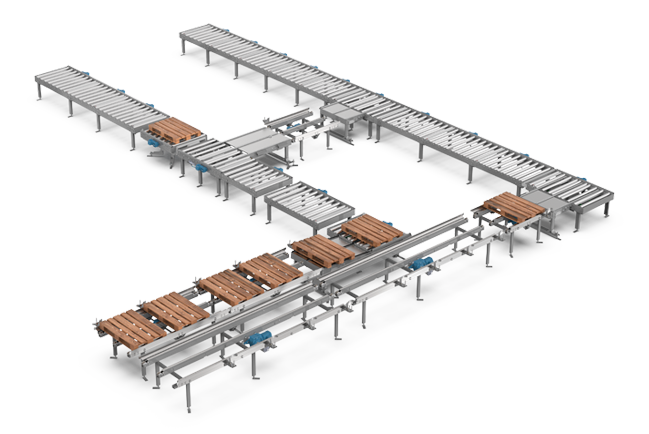

Our advanced palletizing systems represent a comprehensive and automated solution, featuring a highly efficient robotic system. This system enables the palletization of multiple lines on the same robot, adeptly handling complex setups and allowing for the simultaneous production of multiple pallets. The flexibility of our approach is reflected in the tailor-made design of each system, adapting it to the specific needs of the customer, including factors such as product types, palletizing patterns, speed, and space constraints.

Our commitment to excellence extends even to extreme environmental conditions, such as storage refrigeration cells at -30 °C. We ensure that our systems operate with precision and reliability even in such environments. The total integration of the systems by STIM includes accurate management of product and packaging codes, ensuring impeccable traceability from the moment of entry into the system to the completion of the pallet. Additionally, we offer the option to integrate barcode, QR code, or vision reading systems for quality control and package integrity detection.

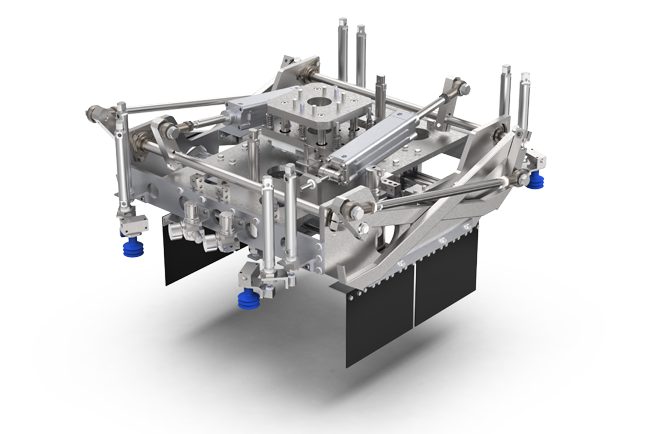

The grippers of our robots are custom-designed to safely handle a wide range of products, ensuring a secure grip and precise placement, avoiding any potential damage. Our attention to detail and personalized solutions set us apart in ensuring our customers reliable and optimal performance in the palletizing process.