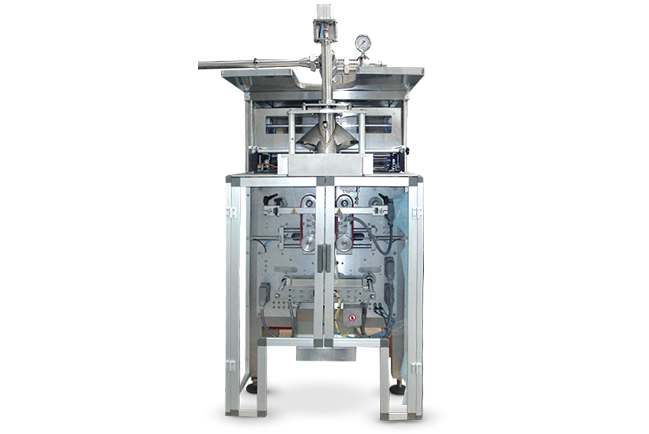

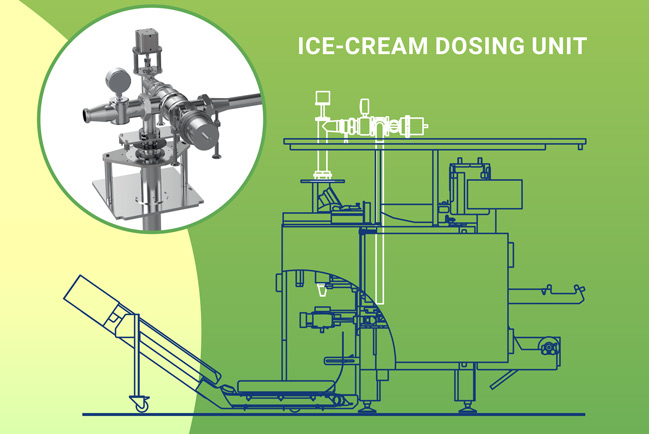

A sequentially operated vertical packaging machine equipped with an electronic management system. This machine is ideal for shaping, filling products such as ice cream, liquid or powdered milk, and sealing flow-pack bags from a single wrapping coil.

Main features of the machine:

Possible bag sizes:

- Width: from 60 mm to 360 mm

- Length: from 60 mm to 500 mm

Coil dimensions:

- Width: from 140 mm to 750 mm

- Outer diameter: 400 mm

- Inner diameter: 50 mm

- Maximum theoretical speed: 40 CPM (Cycles per Minute)

The base machine is equipped with a wide range of high-precision features and controls, optimized to ensure maximum efficiency in product packaging.

The basic machine is equipped with:

- Heat-sealed jaws for cellophane, laminates, and other materials, ensuring precise and sturdy sealing.

- Separate drive for film traction belts and alternating motion sealing jaws, allowing precise and optimized control of machine functions based on the product and wrapping material, reducing waste.

- Alternating motion jaws, operated by a pneumatic piston.

- Pneumatically operated longitudinal sealing pad.

- Pneumatically operated cutting blades for a clean and precise cut of the wrapping material.

- System of rotating brushes for cleaning the film traction belts with a quick-release device, to maintain the machine in optimal operating conditions.

- Electronic device for control and adjustment of the package length to adapt to different product sizes.

- Independent control of each sealing bar through 3 high-precision temperature controllers, ensuring reliable sealing.

- A series of sealing jaws suitable for a variety of materials, including polypropylene films, polyester-based laminates, polyamide, paper, and foil, with a digital control system for maximum flexibility.

- Capacity to store up to 35 different programs for quick package setup.

- Machine diagnostic system to facilitate maintenance and issue resolution.

- Use of a Siemens PLC and a touchscreen for intuitive and reliable control.

- Synchronization with a printer, labeler, weigher, and other units, all controlled by the same machine PLC for increased efficiency.

- Safety protections ensured by Interlock safety switches for maximum operator safety.

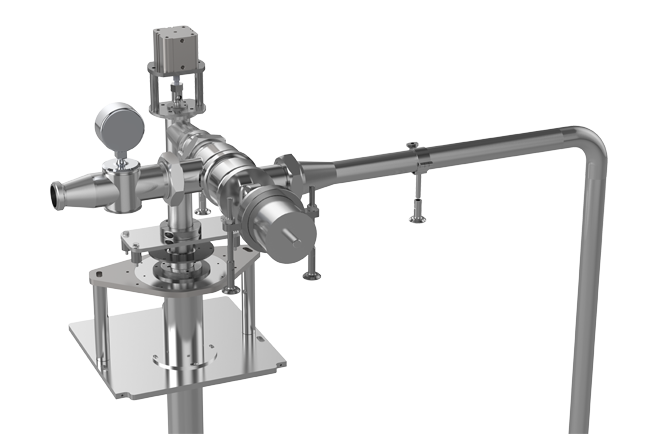

- AISI 316 stainless steel pneumatic dosing system for optimal durability and hygiene.

- Brushless film traction system for silent and efficient operation.

- Long 450/500 mm sealing bar for packaging products of various sizes.

- Photocell for print centering to ensure accurate packaging.

- Film coil with automatic centering system to reduce material waste.

- Product format with AISI 304 stainless steel forming tube.

- AISI 304 stainless steel discharge belt for the finished product, with a horizontal section for extracting large-sized products and an inclined section with adjustable slope.

- Washable and hygienic belt with a modular polypropylene chain for maximum cleanliness.

- Motorized unwinding unit for constant film advancement.

- Pneumatically operated dosing nozzle for ice cream/liquids in AISI 316 stainless steel.

- Semi-automatic system for changing the wrapping coil to reduce downtime.

- "New design" cutting blades to reduce the risk of dirt accumulation.

Note: The coding device is not included but is available upon request for adding printed information to the packages.